Application Solution for Catering Kitchen

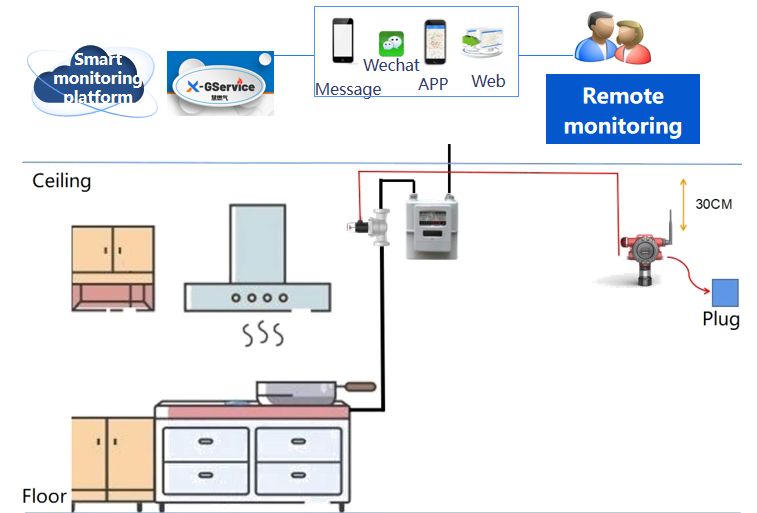

1.Commercial solutions for natural gas

- Detector installation plan

Set up in kitchen rooms, installed in areas prone to gas leakage and flow, detectors should be installed on walls that are more than 1 meter, less than 8 meters away from the release source, and 0.3m away from the ceiling. Connect the power line to the socket, and the output line to the industrial solenoid valve.

- Industrial solenoid valve installation plan

The industrial solenoid valve is installed before and after the gas meter, and is connected to a commercial detector through a connecting wire to receive the valve closing signal.

| Product model | Product description |

| DRQF-25-0.01/BT | AC220V Input、Cast aluminum(aluminum ZL104)、Flange, low pressure, normally closed |

Industrial solenoid valve

| Product model | Product description |

| GTY-AEC2335bN | Detection gas: natural gas; NB-IOT communication; 220V power supply; Dual output; LED concentration display; Integrated sound and light alarm |

Independent commercial detector

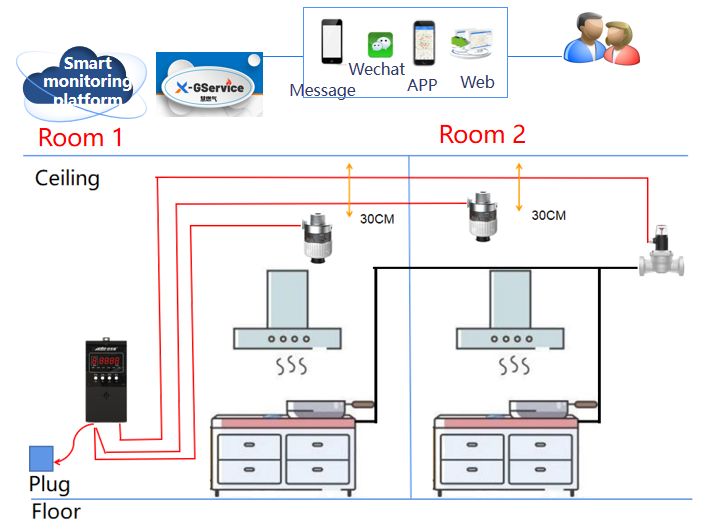

- Installation plan for detector system

The detector should be installed in two rooms or in places where gas is prone to leakage and flow at a distance of no more than 15 meters. The detector should be installed on a wall that is more than 1 meter away from the release source, less than 8 meters away, and 0.3m away from the ceiling. The power cord should be connected to the controller for power supply; The controller is installed in a place that is easy to manage and operate, powered by 220V, with four connecting wires connected to sockets, detectors, and industrial solenoid valves.

- Industrial solenoid valve installation plan

The industrial solenoid valve is installed before and after the gas meter, and is connected to the controller through a connecting wire to receive the valve closing signal.

Industrial solenoid valve

| Product model | Product description |

| DRQF-25-0.01/BT | AC220V input, cast aluminum (aluminum ZL104), flange, low voltage, normally closed |

Commercial combustible gas detector

| Product model | Product description | Notes |

| GTY-AEC2330a | Catalytic combustion, diffusion, ABUS+, methane/propane | Explosion-proof certificate |

Alarm controller

| Product model | Product description |

| AEC2305bN | Wall mounted, digital display, AC220V power supply, NB-IOT communication,pulse output bus communication (2 signal lines, 2 power lines),2 sets of outputs,RS485 interface function |

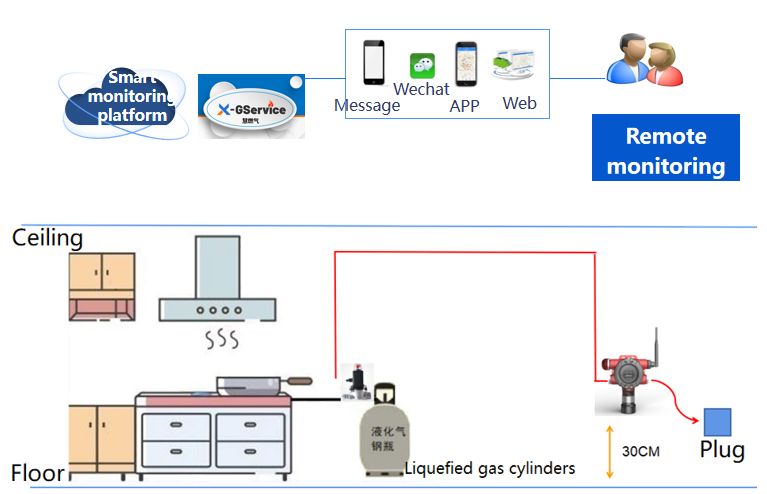

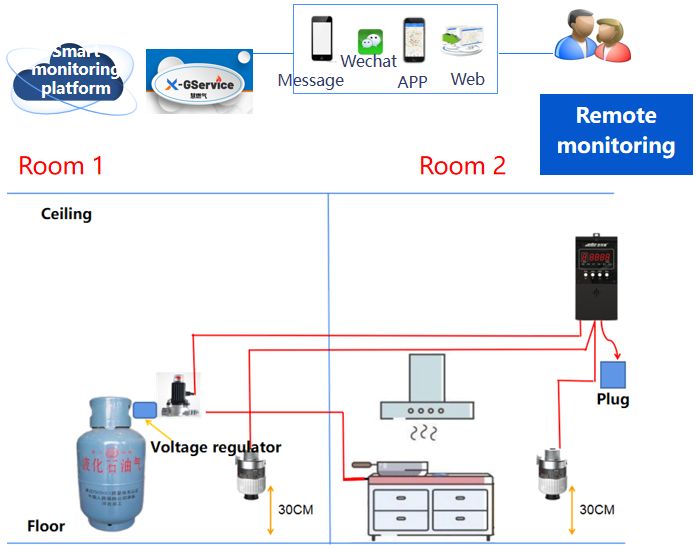

2.Commercial solutions for liquefied gas

- Detector installation plan

Set up in kitchen rooms, installed in areas prone to gas leakage and flow, detectors should be installed on walls that are more than 1 meter, less than 4 meters away from the release source, and 0.3m above the ground. Connect the power line to the socket and the output line to the liquefied gas solenoid valve.

- Installation plan for liquefied gas solenoid valve

The liquefied gas solenoid valve is installed at the rear end of the pressure regulator at the outlet of the liquefied gas tank, and is connected to a commercial detector through a connecting wire to receive the valve closing signal.

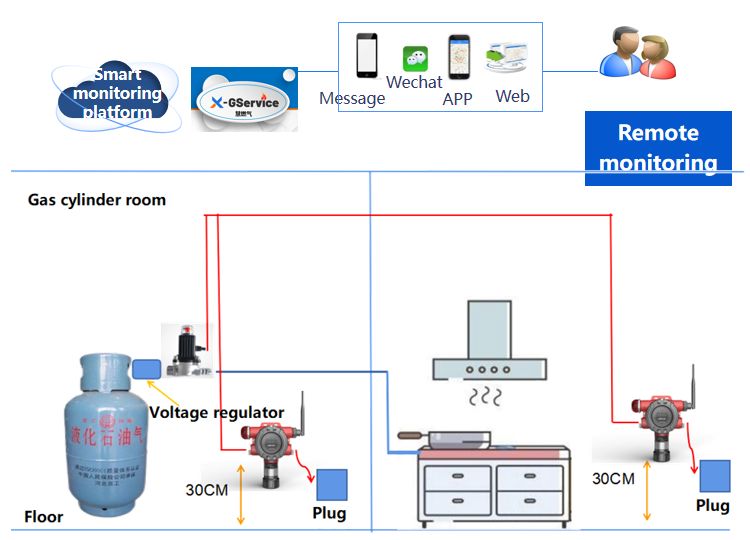

- Detector installation plan

Set up in kitchen and gas rooms, installed in places where gas is prone to leakage and flow. Detectors should be installed on walls that are more than 1 meter, less than 4 meters away from the release source, and 0.3m above the ground. Connect the power line to the socket and the output line to the liquefied gas solenoid valve.

- Installation plan for liquefied gas solenoid valve

The liquefied gas solenoid valve is installed at the rear end of the pressure regulator at the outlet of the liquefied gas tank, and is connected to a commercial detector through a connecting wire to receive the valve closing signal.

Liquefied gas solenoid valve

| Product model | Product description |

| DRQF-15-0.4/KYLHS | Normally open, DN15, medium pressure (0-0.4MPa), nominal pressure PN16, straight through, cast aluminum (aluminum ZL104) |

Independent commercial detector

| Product model | Product description |

| GTY-AEC2335bN | Detection gas: natural gas; NB-IOT communication; 220V power supply; Dual output; LED concentration display; Integrated sound and light alarm |

- Installation plan for detector system

The detector should be installed in two rooms where gas is prone to leakage and flow. The detector should be placed on a wall that is more than 1 meter, less than 4 meters away from the release source, and 0.3m above the ground. Connect the power cord to the controller for power supply; The controller is installed in a place that is easy to manage and operate, with a 220V power supply; Four connecting wires are respectively connected to sockets, detectors, and liquefied gas solenoid valves.

- Installation plan for liquefied gas solenoid valve

The liquefied gas solenoid valve is installed before and after the gas meter, and is connected to the controller through a connecting wire to receive the valve closing signal.

Commercial combustible gas detector

| Product model | Product description |

| DRQF-15-0.4/KYLHS | Normally open, DN15, medium pressure (0-0.4MPa), nominal pressure PN16, straight through, cast aluminum (aluminum ZL104) |

Alarm controller

| Product model | Product description |

| AEC2305bN | Wall mounted, digital display, AC220V power supply, NB-IOT communication, pulse output bus communication (2 signal lines, 2 power lines),2 sets of outputs, RS485 interface function |

Commercial combustible gas detector

| Product model | Product description | Notes |

| GTY-AEC2330a | Catalytic combustion, diffusion, ABUS+, methane/propane | Explosion-proof certificate |