New Pump suction PID Products Introduction (Self developed sensors)

GQ-AEC2232bX-P

What is VOC gas?

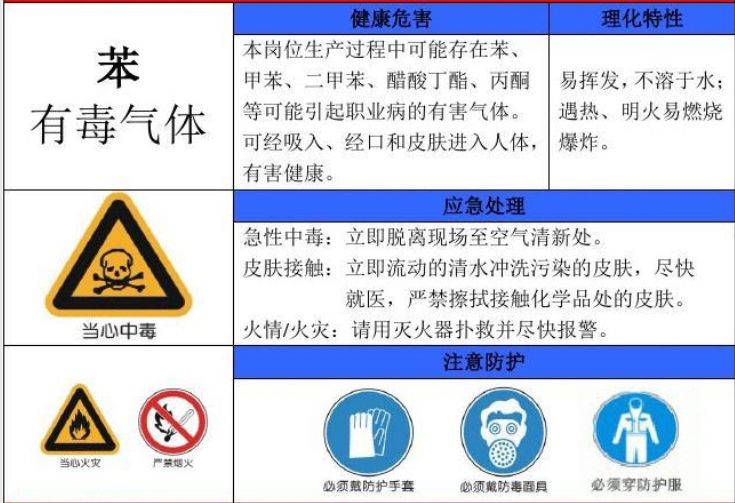

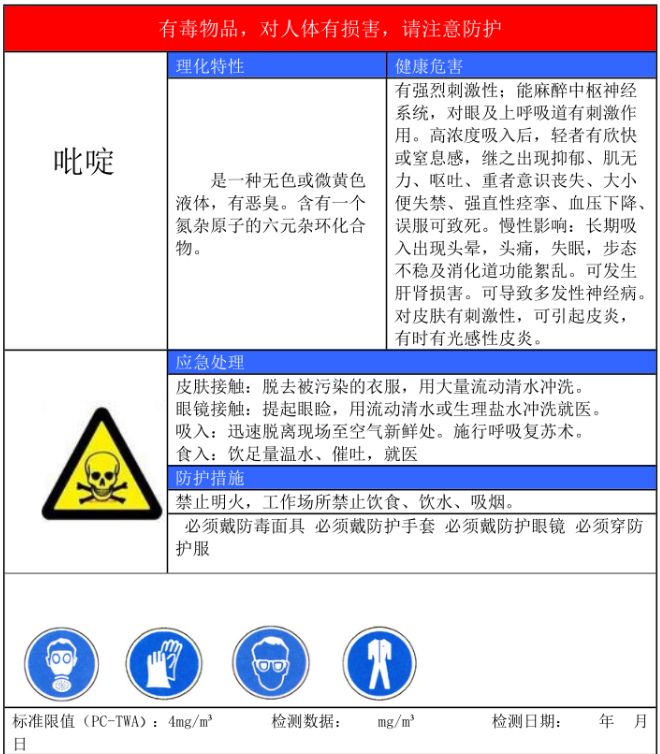

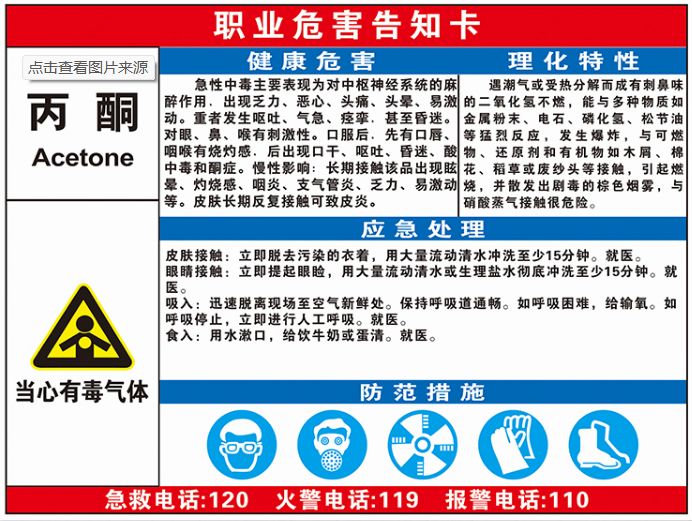

VOC is the abbreviation for volatile organic compounds. In the ordinary sense, VOC refers to the command of volatile organic compounds; However, in terms of environmental protection, it refers to a class of volatile organic compounds that are active and harmful. The main components of VOC include hydrocarbons, halogenated hydrocarbons, oxygen hydrocarbons, and nitrogen hydrocarbons, including benzene series compounds, organic chlorides, fluorine series, organic ketones, amines, alcohols, ethers, esters, acids, and petroleum hydrocarbons. And a class of compounds that pose a significant threat to human health.

What are the hazards of VOC gas?

What are the detection methods for VOC gases?

What is the principle of PID detector?

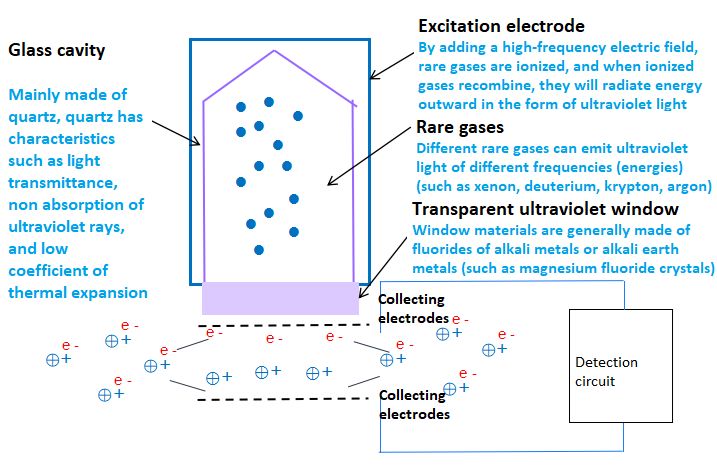

Photoionization (PID) detection utilizes the ultraviolet radiation generated by the ionization of an inert gas by a high-frequency electric field to ionize the gas molecules under test. By measuring the current intensity generated by the ionized gas, the concentration of the gas under test is obtained. After being detected, ions recombine into the original gas and vapor, making PID a non-destructive detector.

Self developed PID sensor

Intelligent excitation electric field

Long life

Using intelligent compensation to excite the electric field, significantly extending the life of sensors (life>3 years)

Latest sealing technology

High reliability

The sealing window adopts magnesium fluoride material combined with a new sealing process, effectively avoiding rare gas leakage and ensuring the lifespan of the sensor.

Window gas gathering ring

High sensitivity and good accuracy

There is a gas gathering ring at the UV lamp window, which makes gas ionization more thorough and detection more sensitive and accurate.

Teflon material

Corrosion resistance and strong stability

The parts illuminated by ultraviolet lamps are all made of Teflon material, which has strong anti-corrosion ability and can slow down oxidation by ultraviolet and ozone.

New chamber structure

Self cleaning and maintenance free

New type of chamber structure design with added flow channel design inside the sensor, which can directly blow and clean the sensor, effectively reducing the dirt on the lamp tube and achieving maintenance free sensor

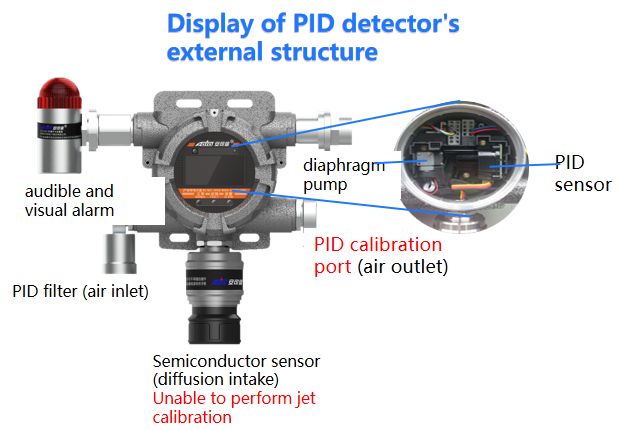

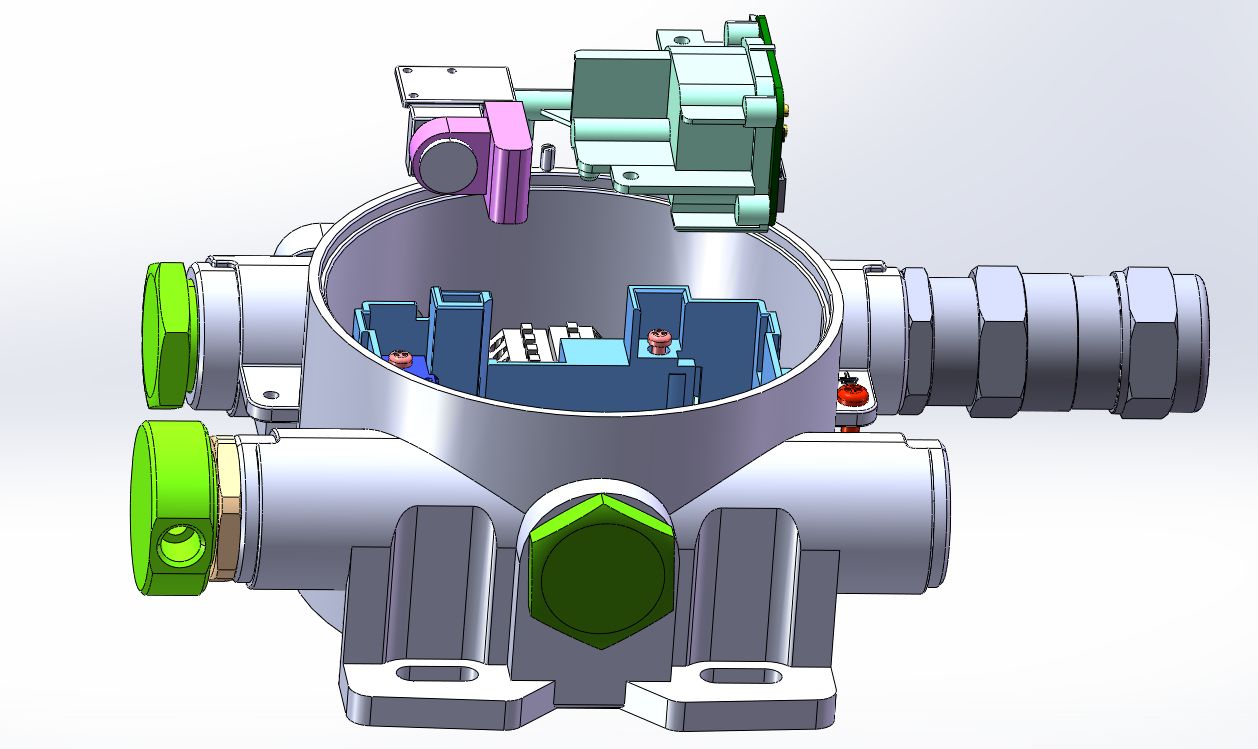

The pump suction detector designed specifically for the new PID sensor allows the sensor to achieve maximum efficiency, providing better detection results and a better user experience

The anti-corrosion level reaches WF2 and can adapt to various high humidity and high salt spray environments (Spraying fluorocarbon paint anti-corrosion material on the shell)

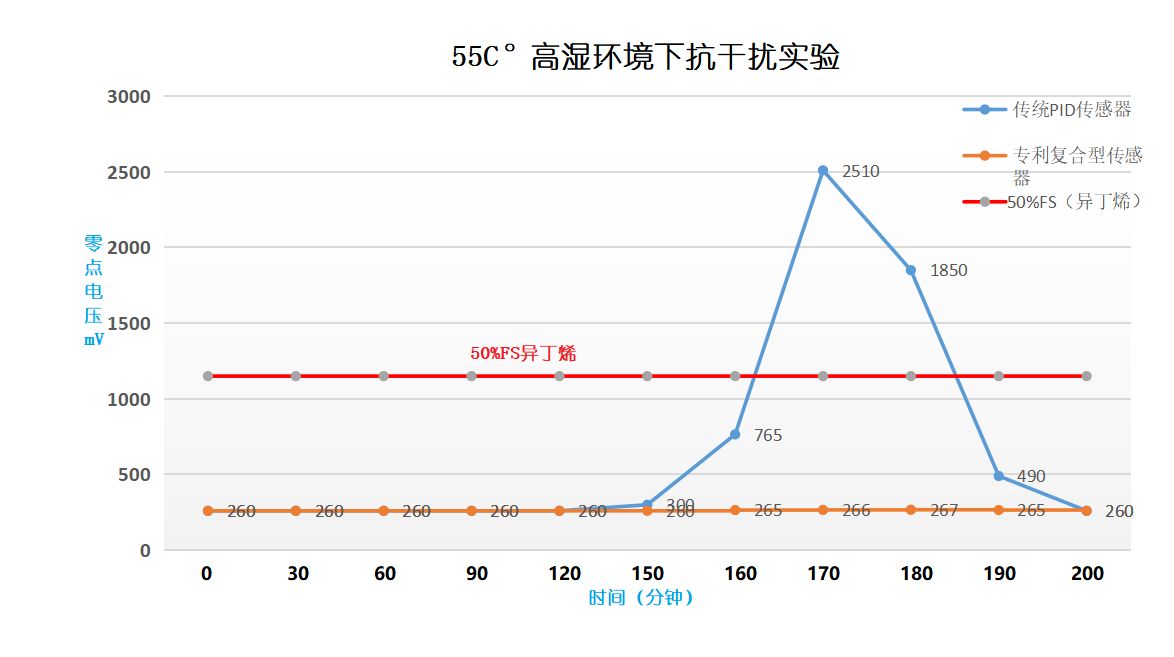

Advantage 1: No false alarms in high temperature and humidity environments

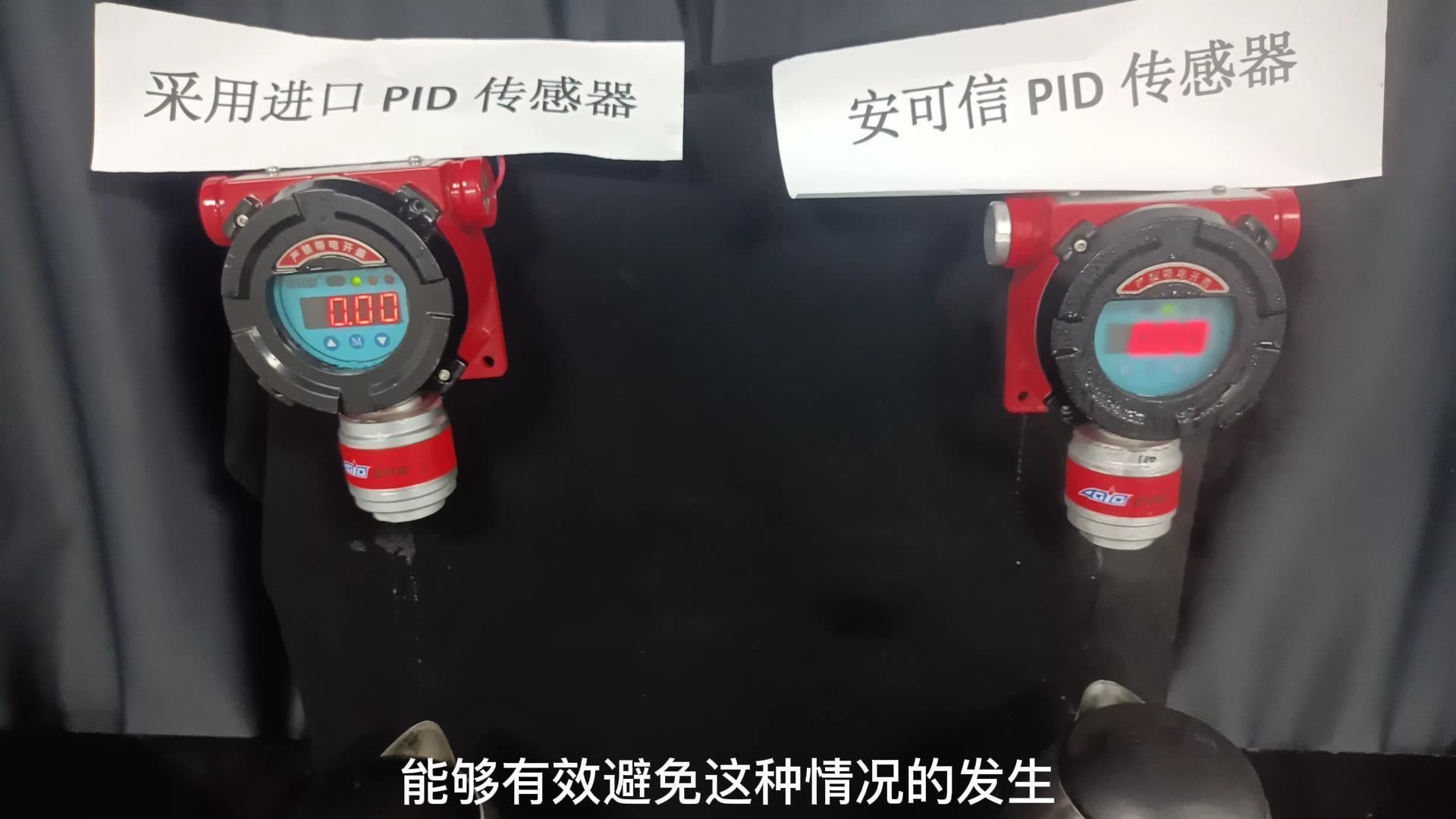

The experiment simulated a comparative experiment between traditional PID detectors and dual sensor PID detectors in a high humidity environment of 55 ° C. It can be seen that traditional PID detectors have significant concentration fluctuations in this environment and are prone to false alarms. And the Anxin patented dual sensor PID detector hardly fluctuates and is very stable.

Advantage 2: Long life and maintenance free

New PID sensor

combinative monitoring

Multi-stage filtration

Realize a PID sensor with a lifes of over 3 years and maintenance free during its life

Significant breakthrough comparable to the life of catalytic sensors

Advantage 3: Modular design, convenient installation and maintenance

PID sensor module, can be quickly opened and disassembled for maintenance

Modular pump, quick to plug and replace

Each module has achieved modular design, and all vulnerable and consumable parts have been replaced quickly and conveniently.

Comparative experiment, comparing high and low

Comparison with untreated imported PID sensor brands

Comparative testing with a certain brand of detectors on the market

Technical Parameter

| Detection Principle | Composite PID sensor | Signal transmission method | 4-20mA |

| Sampling method | Pump suction type (built-in) | Accuracy | ±5%LEL |

| Working voltage | DC24V±6V | Repeatability | ±3% |

| Consumption | 5W(DC24V) | Signal transmission distance | ≤1500M(2.5mm2 ) |

| Pressure Range | 86kPa~106kPa | Operation temperature | -40~55℃ |

| Explosion proof mark | ExdⅡCT6 | Humidity range | ≤95%,no condensation |

| Shell material | Cast aluminum (fluorocarbon paint anti-corrosion) | Protection grade | IP66 |

| Electrical interface | NPT3/4"Pipe thread (inner) | ||

Regarding the questions with PID detectors?

Answer: The product launched this time mainly replaces our company's latest developed PID sensor, which has changed the air chamber structure (flow channel design) and power supply mode. The special flow channel design can reduce light pollution and achieve wiping free lamp tubes through multi-level filtering. Due to the built-in intermittent power supply mode of the sensor, intermittent operation is smoother and more intelligent, and combined detection with dual sensors achieves a lifespan of more than 3 years.

Answer: The main functions of a rain box are to prevent rainwater and industrial steam from directly affecting the detector. 2. Prevent the impact of high temperature and humidity environments on PID detectors. 3. Block some dust in the air and delay the lifespan of the filter. Based on the above reasons, we have equipped a rainproof box as standard. Of course, adding a rainproof box will not have a significant impact on the gas response time.

Answer: It should be noted that 3-year maintenance free means that the sensor does not need to be maintained, and the filter still needs to be maintained. We suggest that the maintenance time for the filter is usually 6-12 months (shortened to 3 months in harsh environmental areas)

Answer: Without the use of dual sensors for joint detection, our new sensor can achieve a life of 2 years, thanks to our newly developed PID sensor (patented technology, the general principle can be seen in the second section). The working mode of semiconductor+PID joint detection can achieve a life of 3 years without any problems.

Answer: a. Isobutene has a relatively low ionization energy, with an Io of 9.24V. It can be ionized by UV lamps at 9.8eV, 10.6eV, or 11.7eV. b. Isobutene is low toxicity and a gas at room temperature. As a calibration gas, it poses little harm to human health. c. Low price, easy to obtain

Answer: It will not be damaged, but high concentrations of VOC gas can cause VOC gas to adhere to the window and electrode for a short period of time, resulting in sensor unresponsiveness or reduced sensitivity. It is necessary to immediately clean the UV lamp and electrode with methanol. If there is a long-term presence of VOC gas exceeding 1000PPM on site, using PID sensors is not cost-effective and non dispersive infrared sensors should be used.

Answer: The general resolution that PID can achieve is 0.1ppm isobutene, and the best PID sensor can achieve 10ppb isobutene.

The intensity of ultraviolet light. If ultraviolet light is relatively strong, there will be more gas molecules that can be ionized, and the resolution will naturally be better.

The luminous area of the ultraviolet lamp and the surface area of the collecting electrode. The large luminous area and the large collection electrode area naturally result in high resolution.

The offset current of the preamplifier. The smaller the offset current of the preamplifier, the weaker the detectable current. If the bias current of the operational amplifier is large, the weak useful current signal will be completely submerged in the offset current, and good resolution cannot be achieved naturally.

The cleanliness of the circuit board. Analog circuits are soldered onto circuit boards, and if there is a significant leakage on the circuit board, weak currents cannot be distinguished.

The magnitude of the resistance between current and voltage. The PID sensor is a current source, and the current can only be amplified and measured as a voltage through a resistor. If the resistance is too small, small voltage changes cannot be achieved naturally.

The resolution of the analog-to-digital converter ADC. The higher the ADC resolution, the smaller the electrical signal that can be resolved, and the better the PID resolution.