Call Support 24/7

+86-28-68724242

product

High Quality Gas Control Panel - Gas Alarm Controller AEC2392b – Action

High Quality Gas Control Panel - Gas Alarm Controller AEC2392b – Action Detail:

Technical Specifications

|

Item |

Data |

||

|

Operating voltage |

AC220V±15% (50Hz±1%) |

||

|

Capacity |

1~4 points |

||

|

Types of gas detected |

%LEL, 10-6, %VOL and switching value signals |

||

|

Range |

Combustible gas: max. 100 (%LEL) Toxic gas: max. 9,999 (10-6) Oxygen: max. 100 (%VOL) |

||

|

Power consumption |

≤10W (excluding supporting equipment) |

||

|

Load capacity |

the max. output current of a single service circuit 24V ≤300mA |

||

|

Environmental condition for operating |

Temperature: 0℃~40℃; relative humidity≤93%RH |

||

|

Alarming mode |

audible-visual alarm |

||

|

Value indication error |

±5%FS |

||

|

Alarming error |

±15% of the alarming concentration |

||

|

Display mode |

nixie tube |

||

|

Signal transmission |

4~20mA standard signal (three-wire system) |

||

|

Signal transmission distance |

≤1000m (1.5mm2) |

||

|

Output |

five sets of relay contact signals, with the capacity of 10A/DC24V or 10A/AC220V RS485 bus interface (standard MODBUS protocol) |

||

|

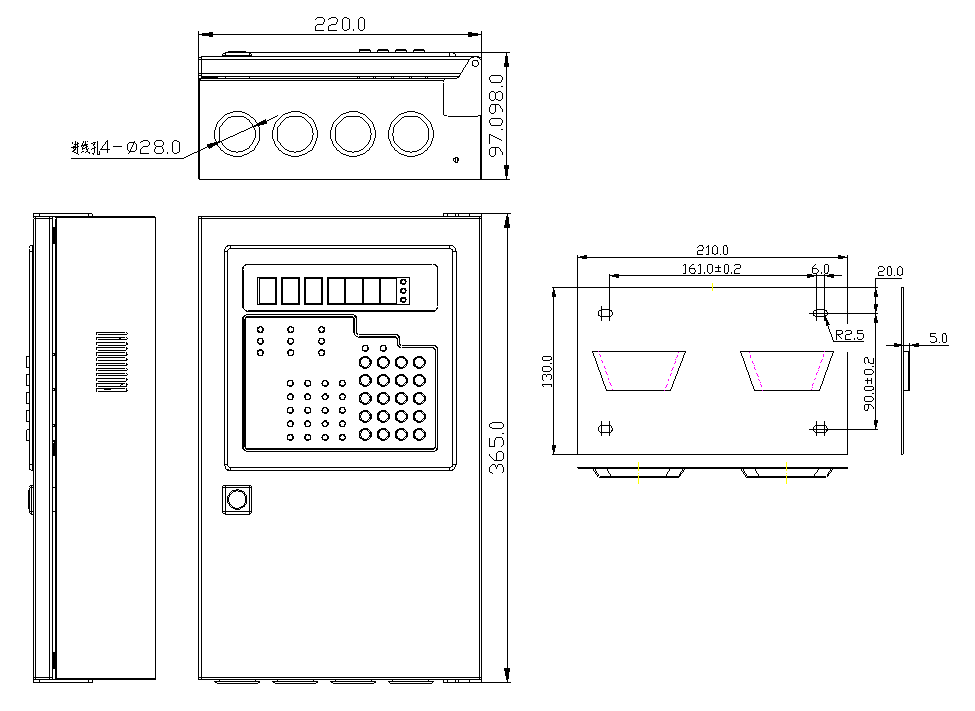

Boundary dimensions |

Length × width × thickness: 365mm×220mm×97mm |

||

|

Gross weight |

about 6kg |

||

|

Standby power supply |

12VDC/2Ah×2 |

||

|

Mounting mode |

wall-mounted |

||

|

Adaptive detectors |

Gas detectors: GT-AEC2232bX, GQ-AEC2232bX, GT-AEC2232aT, AEC2338, GQ-AEC2232bX -P, AEC2338-D Fan linkage box: JB-ZX-AEC2252F Solenoid valve linkage box: JB-ZX-AEC2252B |

||

Major Features

● Meet the need of connecting standard 4-20mA current signal detectors at 1-4 point locations;

● With a small size, the product can be wall-mounted easily. Two sets or more can be installed side by side to meet customer’s demands for more point locations (wall mounting of 8, 12, 16 or more point locations can be realized through gapless combination);

● Monitoring and display of real-time concentration (%LEL, 10-6, %VOL) as well as switching value signals of combustible gas, toxic gas and oxygen (default is combustible gas detector. No setting is required. It is available for use after being installed and electrified);

● Each circuit links one switching value output. If necessary, linking programming setting can be realized through the menu. Each product has one RS485 digital interface to communicate with the host computer;

● The visual range is farther and the visual angle is wider. Concentration contains 4 effective digits. Display with an accuracy of 9999~0.001 is available;

● Save the latest 999 alarming records and 999 failure records.

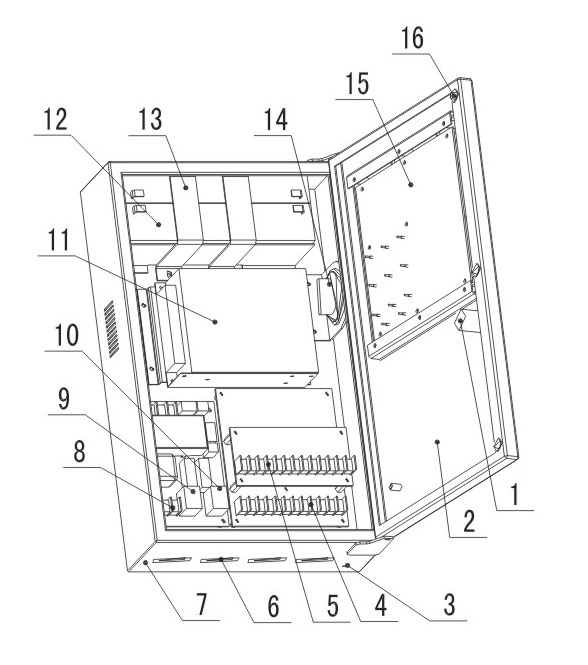

Structure

1. Side lock

2. Cover

3. Casing ground

4. User connection terminal

5. User connection terminal

6. Incoming hole

7. Bottom box

8. Power supply terminal

9. Switch of main power supply

10. Switch of standby power supply

11. Switch power supply

12. Standby battery

13. Battery holder

14. Horn

15. Control panel

16. Anti-collision mat

Panel Marks And Mounting Instructions

● Make 4 or 6 mounting holes (hole depth: ≥40mm) in a wall according to the requirements for the size among mounting holes (hole symbols 1 – 6) for mounting the hanging plate;

● Insert a plastic expansion bolt into each mounting hole;

● Fix the hanging plate onto the wall and fasten it onto the expansion bolts with 4 or 6 self-tapping screws (ST4.2×25);

● Hang the hanging parts at the bottom of the controller onto location A at the bottom board to complete mounting of the controller.

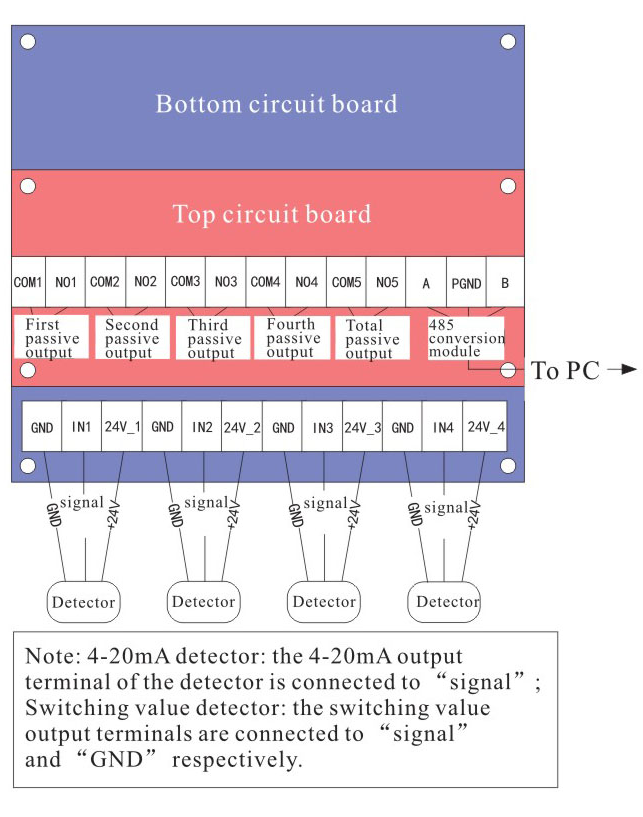

System Configuration

AEC2392b has 4 sets of branch-line connection terminals that can be connected to the branch-line communication equipment manufactured by the company such as detectors AEC2232b, AEC2232bX, GQ-AEC2232b, GQ-AEC2232bX and AEC2232aT, or other transmitters with 4~20mA signal outputs to monitor and control the gas concentration at site. Meanwhile, remote logical control over external equipment (in-situ audible-visual, solenoid valves and fans, etc.) can be realized through 5 sets of built-in programmable modules. In addition, remote communication with the monitor system can be realized through the RS485 communication interface.

Product detail pictures:

Related Product Guide:

Bear "Customer first, High quality first" in mind, we perform closely with our consumers and provide them with efficient and experienced services for High Quality Gas Control Panel - Gas Alarm Controller AEC2392b – Action , The product will supply to all over the world, such as: Hanover, Angola, Moscow, We adopted technique and quality system management, based on "customer orientated, reputation first, mutual benefit, develop with joint efforts", welcome friends to communicate and cooperate from all over the world.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.